Case Study

Automating food processing systems

A group of youth in Lincoln, Nebraska used technology to simplify systems in the food industry.

The students paired the with a Food Compliance company to solve data connection issues in the industry.

Details

Fall, 2018

Lincoln, Nebraska

Categories

UpStarts Tech

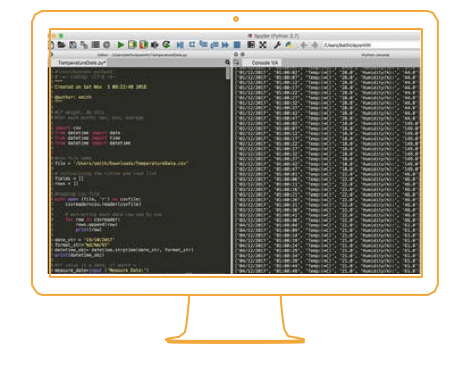

The students developed a soultion to automate food procsessing. This innovative solution reduced error, increased productivity, and reduced health and safety risks.

There are monitoring devices on food processing equipment, such as temperature, pressure, and flow rate, but those devices communicate to each other nor supply their data anywhere. The data has to be physically collected, which increases food safety risks and costs for the business operation. The process requires precision and manual labor. Failing to collect the data properly increases the possibilities of health and safety risks, increasing business risks as well. The students created an automated process that links data to a raspberry pi, which is a mini high-powered computer. The data that is collected in the interface can then be interpreted and used. The students had the opportunity to see their soultion in action and see the impact their solution will have on the user.